U Shaped Nickel Plated Copper Bus Bar 1-20mm Thickness For Conduct Electricity

Detail Description

Material: Copper

Hole Size: M4, M5, M6, M8.M10, M12, M14, M16, M20 etc

Hole Type: Round, Oval-Shaped, Thread etc

Busbar Thickness: 1-20mm

Application: Conduct Electricity, New Energy Vehicle, Battery Connection

Insulation: Heat Shrink Sleeves or PVC Dipping Cover

Current Rating: 100A-6000A

Character: Environmental Protection

Shape: U shape

Production Process: Welding

Technical features of copper bus bar:

1. Material is of fire-resistant PVC and redl copper

2. Current rating is up to 125A

3. Rated voltage is up to 415V

4. Applicable ambient temperature -25~+50

5. Standard length 1m, other length tol be made upon request.

6. Good conductivity, low contact resistance, safe and reliable.

Laminated and Flexible Copper Bus Bars are developed from high conductivity based electrolytic grade copper sheets/foils. These are made using a press welding procedure where individual copper strips are fused through applying direct current as well as pressure without the need of foreign material.

The process assures minimum resistance and helps in increasing products' service life as well as bringing a reduction in downtime. Further, these also come with superior mechanical & electrical properties at high temperatures.

| Material |

T2 99.95% copper foils/sheet. C1100,C11000, Cu-ETP, |

| Copper Foils Thickness |

0.1mm, 0.2mm, 0.3mm, 0.5mm |

| Surface Finishes |

Electro brush Silver Plating |

| Tank Nickel or Tin Plating |

| Production Process |

High Ampacity Flexible Connection |

| Molecularly Fused Laminates Ends |

| High DC Current Under Pressure Welding |

| Current |

Typical: up to 2000 A |

| Possible: Up to 5,000 A |

| Flex parts of length |

Up to 6.6 ft.(2meters long) |

| Width |

Up to 6.0 inch (152mm ) |

| Max.Oeveall Thickness |

1.25 inch (32mm) |

| Testing |

Resistance, Temperature Rise, Conductivity, Insulation |

| Sample |

Free |

2. Trade Information

| Payment Method |

T/T or L/C |

| Trade Terms |

EXW / FOB / CIF |

| Payment Terms |

30% deposit after signing contract, and the balance should be paid before shipment or after sending B/L copy |

| Delivery way |

By sea, land and air |

| Delivery Time |

According to the quantity |

3. Why choose our company:

► We are manufacturers of bus bars since year of 2001 with automatic machines, professional production and inspection teams.

► Our staff s are all with more than 5 years working experience. We will supply you considerate pre-sale and after sale service

► Fast delivery for samples and bulk quantity,we have raw material in stock

► OEM/DEM is welcome.

► We are factory with competitive price and punctual delivery time.

► Inspect every product before delivery to ensure high quality.Our products have gained ISO9001 and IATFcertificate.

► Guarantee is 15-20years for flexible copper bus bar.

4. The feature of our copper busbar:

► Excellent electrical conductivity.

► High bonding strength.

► Pure T2 copper.

► Copper foil busbar to be used in transformer has a profile to allow for transformer thermal expansion and contraction

► Made of copper foil provides maximum flexibility and reduces vibration . It is typically used for copper busbar systems, transformer connections and High Voltage Switchgear.

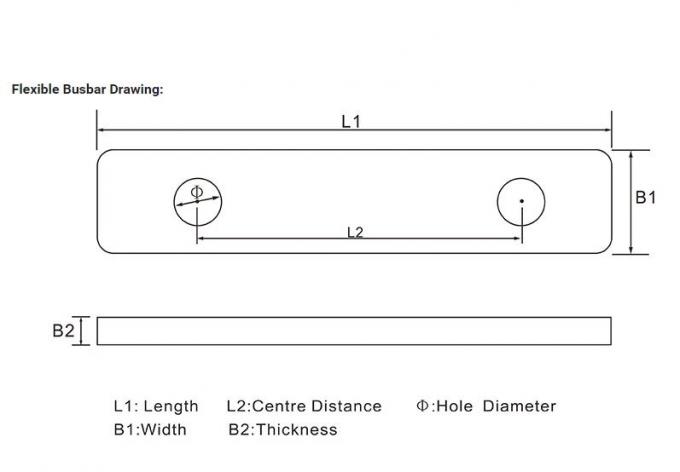

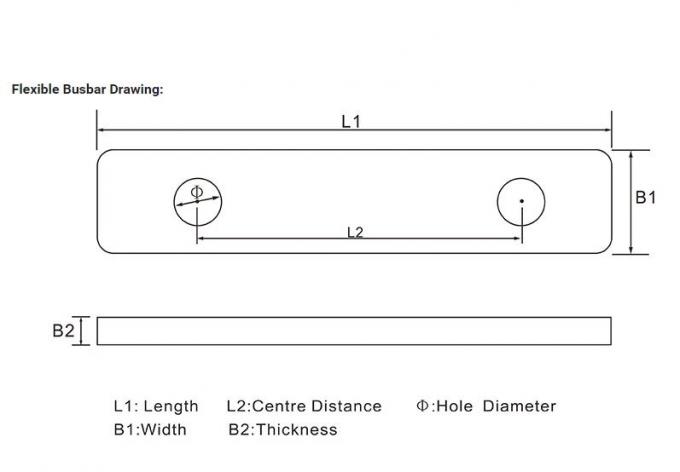

Detail Size:

| Type |

Holes |

Specification

(mm) |

Actual Thickness

and Width(mm) |

Centre Distance

(mm) |

Overall Length

(mm) |

Zero

busbar |

5 |

2*15 |

1.5*15 |

85 |

98 |

| 2*20 |

1.8*20 |

93 |

108 |

| 7 |

2*15 |

1.5*15 |

108 |

121 |

| 2*20 |

1.8*20 |

120 |

135 |

| 10 |

2*15 |

1.5*15 |

142 |

156 |

| 2*20 |

1.8*20 |

160 |

175 |

Floor

busbar |

5 |

2*15 |

1.5*15 |

91 |

103 |

| 2*20 |

1.8*20 |

99 |

112 |

| 7 |

2*15 |

1.5*15 |

115 |

128 |

| 2*20 |

1.8*20 |

125 |

138 |

| 10 |

2*15 |

1.5*15 |

149 |

162 |

| 2*20 |

1.8*20 |

165 |

178 |

Advantage

Laminated Flexible Jumpers advantages:

1) Welding press many laminations improve electrical conductivity and add the transmission of current.

2) The feature of flexible enable us to be made busbars in various types.

3) Laminated copper shunts are flexible and easy to install.

4) Flexible laminate busbar is not easy to be broken after thousands times of bending.

All sizes can be customized. Just send us your drawings, such as PDF, JPEG, PNG,JPG etc.

We will quote for you in 1-2 working days !

Testing Capabilities

| Test Programs |

Tester |

Standard |

Test Result |

| Endurance test |

Endurance meter |

upon your request |

√ |

| Release force test |

Universal material testing machine |

upon your request |

√ |

| Loop resistance,contact resistance test |

Loop resistance testing equipment |

upon your request |

√ |

| Temperature rising test |

Temperature rising meter |

GB/T14048.1-2000 |

√ |

| Electric conductivity test |

Conductivity meter |

YS/T478-2005 |

√ |

| Salt spray test |

Salt spraying meter |

GB/T2423.17-2008 |

√ |

| Thermal ageing, heat vibration test |

Air exchange aging test machine |

upon your request |

√ |

| Coating thickness test |

X-ray coating thickness test |

upon your request |

√ |

| Voltage drop test |

Voltage drop meter |

upon your request |

√ |

FAQ

Q1.Are you factory?

A.Yes,we are factory for copper and aluminum bus bars since year of 2012.You are welcome to visit our factory at your convenient time.

Q1. What is your terms of packing?

A: Generally, we pack our goods in neutral white boxes and brown cartons. If you have legally registered patent,

we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages

before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF, DDU.

Q4. How about your delivery time?

A: Generally, it will take 5-7 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!