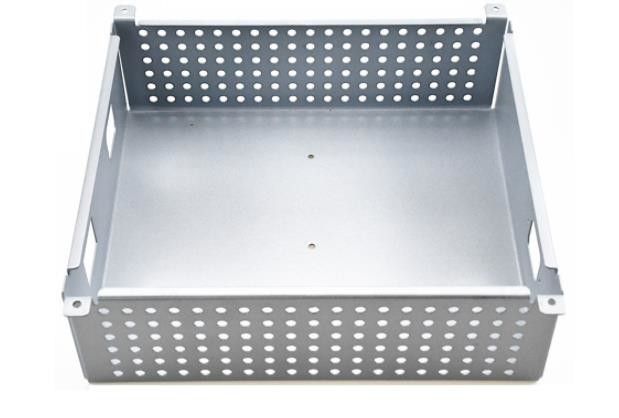

1. Small details make big difference. We promise:All the parts from our company have no sh-arp edge. Holes and screw holes are chamfered for convenient assembly (Under no indication). Every product will be carefully packed to prevent the bump and rust in transit .

2. The craftsmanship of all parts we machined is controlled rigorously, Every product has its own process card and process chart.

3. Our quality inspection procedure is quite strict.it must self-inspected during production, we have flow inspectors and professional inspectors.

4. Each size of product must be tested one to one after completing production and provide quality report.

5. We not only have the world of high-end DMG five-axis linkage machining center, the five-axis linkage turning compound double spindle machining center, compound turning machine,laser cutting machine, CNC shearing machine, flat bed spot-welder, die grinder, steel processing machine, double servo turret-type punch press, banding machine, steel processing machine but also have more than 30 sets of processing machines from Japanese and Taiwanese brands. Our testing equipment are imported from Japanese brand Mitutoyo, such as high-end automatic three coordinate measuring machine, the two coordinate measuring machine, high-quality height gauge and roughness measurement etc.

6. The most important point, we are the entity factory, not trading company. Price is the composition of the actual product quality price. Quality can guarantee more controllable higher than trading company. The price is lower, at least reducing the trade company's service fee.

7. We are a combination of production and trade, industry and trade integration business. So far there are 13 traders for Japanese and European market

8. Because we are more close to our factory, we can understand the actual situation of our factory, we are more professional ,more reasonable and more accurate than trade company. And our language ability is also diversified. We can communication Japanese, English and Russian.

9. We have a good enterprise culture with various professional training programs, early meeting every day to share our work experiences to grown up together happily. We have a great ability to development in the company.

10. There are around 80 staff in our team, everyone has their dream in our company. All of us hold birthday celebration, celebrating Mother's and Father's Day , traveling together. The company respects every employee, when Women's Day coming, we got the beautiful flowers and wishes from brothers. Happiness and care surrounding us since we live here, feeling extremely happy !

Q1. Are you factory?

A. Yes,we are factory for copper and aluminum bus bars since year of 2012.You are welcome to visit our factory at your convenient time.

Q1. What is your terms of packing?

A: Generally, we pack our goods in neutral white boxes and brown cartons. If you have legally registered patent,

we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages

before you pay the balance.

Q3. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and

the courier cost.

Q4. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q5: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

Production Show

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!